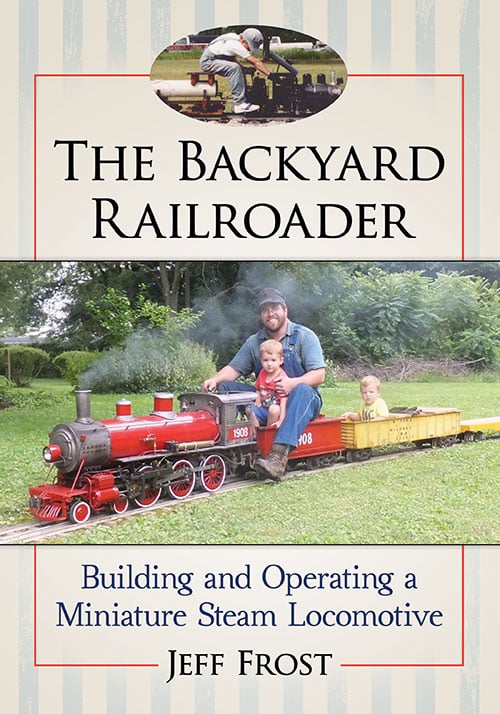

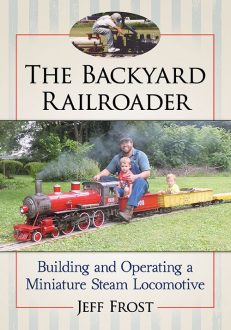

The Backyard Railroader

Building and Operating a Miniature Steam Locomotive

$49.95

In stock

About the Book

Steam locomotives dominated the railways from the 1820s through the 1960s. Today almost all of them have been replaced with electric and diesel engines, yet the fascination surrounding steam-powered trains has not dwindled. A diverse community of enthusiasts—from mechanics to teachers to lawyers—have taken up the hobby of building and running steam locomotives in their own backyards. Drawing on the author’s extensive experience and research, this guide covers the materials, tools, skills and technical information needed to get started or to improve an existing design.

About the Author(s)

Bibliographic Details

Jeff Frost

Format: softcover (7 x 10)

Pages: 306

Bibliographic Info: 358 photos, appendices, index

Copyright Date: 2019

pISBN: 978-1-4766-7281-6

eISBN: 978-1-4766-3164-6

Imprint: McFarland

Table of Contents

Preface 1

Abbreviations 4

Safety Is Rule No. 1 5

Basic Machine Shop Safety 5

Basic Welding/Torching Safety 5

Basic Safety with the Track and Riding 6

Basic Safety with Running Trains 6

Safety Summary 7

Getting Started 8

To Buy or to Build? 8

Buying a Steam Engine 11

Casting Kit versus Building from Scratch 13

Track Basics 24

Book Knowledge versus Experience 29

Suppliers 31

Operating a Steam Engine 35

Basic Checklist for Operating My Steam Engines 35

Water Level in the Boiler 38

Basics of Coal Burners 38

Basics of Oil Burners 40

Sanding the Flues 42

Basics of Propane Burners 43

Firing by Landmarks 43

Speed 44

Water Behavior in the Boiler 45

Carry Over versus Foaming 47

Hooking Up an Engine 49

Hooking Up, Compression and Knocking in the Rods 52

Boilers 54

Water Glass Safety 55

Water Treatment 63

Fusible Plugs 64

Boiler Anodes 65

Boiler Washes 65

Water Circulation in the Boiler 70

Stored Energy in the Boiler 71

Lessons from Gettysburg 73

Signs and Dangers of Low Water 74

Valve Gear 75

Dead Centers 75

Lap and Lead 78

Setting Stephenson Valve Gear 79

Setting Walschaert Valve Gear 83

Inside versus Outside Admission versus Indirect Motion 93

Steam Blowing through the Piston and Valves 95

Uneven Exhausts (Out of Square) 96

Adjusting the Valve Gear on the 4-6-0 98

Building Walschaert Valve Gear for the 4-6-0 101

Lead and Lap/Combination Lever 108

Rebuilding the Valve Gear 110

Systems, Improvements and Why Things Are Done in Certain Ways 112

Potential Reasons for a Poor Steaming Engine 112

Helping an Engine Become a Better Steamer 113

Firebox Arch 114

Large Scale Atomizers 119

Drafting 123

Personal Experience with Axle Pumps and Injectors 128

Tires 132

Automatic Cylinder Cocks 136

Replacing a Crank Pin … and Then Some 139

Piston Problems and Lessons in Threading 147

When There Is No Water in the Glass … Some Food for Thought 151

Revisiting Retubing the Mikado 152

Making an 0-4-0 into a 2-4-0 158

Equalizing 164

Lubrication for the Cylinders 167

Throw, Quarter, Side Rods and Such 170

Wheels and Trucks 172

Basic Lights 174

Dynamo 177

Grates and Ashpan 180

Learning Oil Firing on a 15″ Gauge 4-4-2 185

Propane 192

Long Track, or a Short Loop 195

The Bigger the Better, Right? 195

Equalized Brakes 196

Sanders on the 2-4-0 207

My Experiences in the Hobby 212

The Shay 212

The 0-4-0/2-4-0 214

The Mikado 216

The Ten-Wheeler 219

General Improvements 221

Leaving Home 222

Our Engines 223

Rebuilding the Spirit of Traverse City 233

Getting Back into the Hobby 247

Introducing People to the Hobby 264

Appendix A. Major Parts of a Steam Locomotive 273

Appendix B. Common Questions 275

Appendix C. Common Myths 286

Appendix D. Inspections 290

Appendix E. Tractive Effort and What an Engine Can Pull 294

Index 297